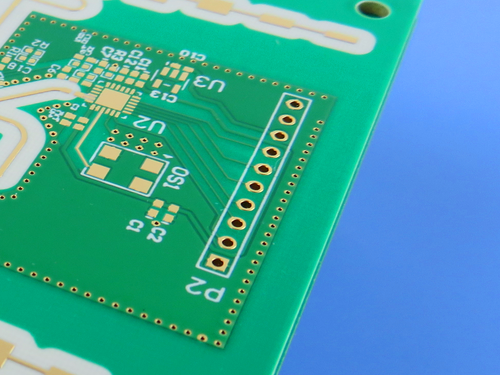

Innovative PCB Solutions: RO4003C and Tg170 FR-4 for High-Frequency Applications

(Custom PCBs are tailored products; the images and specifications provided are for reference only.)

Introduction

Rogers RO4003C materials are proprietary woven glass reinforced hydrocarbon/ceramics known for their exceptional electrical performance, comparable to PTFE/woven glass, while maintaining the manufacturability of epoxy/glass. This design offers superior high-frequency performance and cost-effective circuit fabrication. RO4003C is a low-loss material that can be produced using standard epoxy/glass (FR-4) processes, making it competitively priced.

These materials possess essential properties required by designers of RF microwave circuits, matching networks, and controlled impedance transmission lines. Their low dielectric loss allows RO4003C to be utilized in applications where higher operating frequencies restrict the use of traditional circuit board laminates. Available in various configurations, RO4003C laminates utilize both 1080 and 1674 glass fabric styles, all meeting the same laminate electrical performance specifications. Importantly, RO4003C materials are non-brominated and do not meet the UL 94 V-0 rating.

Features

Features of RO4003C

Dielectric Constant: 3.38 ± 0.05 at 10 GHz

Dissipation Factor: 0.0027 at 10 GHz

Thermal Conductivity: 0.71 W/m/°K

Thermal Coefficient of Dielectric Constant: +40 ppm/°C, ranging from -50°C to 150°C

CTE Matched to Copper: X-axis: 11 ppm/°C, Y-axis: 14 ppm/°C

Low Z-axis Coefficient of Thermal Expansion: 46 ppm/°C

Glass Transition Temperature (Tg): >280 °C

Low Moisture Absorption: 0.06%

Features of S1000-2M

Lower Z-axis CTE for improved through-hole reliability

Excellent Mechanical Processability and thermal resistance

Lead-Free Compatible

Tg: 180°C (DSC), UV Blocking/AOI compatible

High Heat Resistance

Excellent Anti-CAF Performance

Low Water Absorption

PCB Construction Details

| Parameter | Details |

|---|---|

| Base Material | RO4003C and Tg170 FR-4 mixed |

| Layer Count | 6 layers |

| Board Dimensions | 62.5mm x 57.8mm (± 0.15mm) |

| Minimum Trace/Space | 4/7 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias & Buried Vias | Top layer to inner layer 2, inner layer 2 to inner layer 3 |

| Finished Board Thickness | 1.1mm |

| Finished Copper Weight | 1 oz (1.4 mils) for inner/outer layers |

| Via Plating Thickness | 20 μm |

| Surface Finish | Immersion Silver |

| Top Silkscreen | White |

| Bottom Silkscreen | None |

| Top Solder Mask | Matt Blue |

| Bottom Solder Mask | Matt Blue |

| Impedance Control | 90 ohm on 4 mil / 7 mil traces/gaps top layer |

| Print Series Number | Included |

| Via Filling | 0.3mm via filled and capped |

| Electrical Testing | 100% electrical test prior to shipment |

PCB Stackup

Copper Layer 1: 35 μm

RO4003C: 0.305 mm (12 mil)

Copper Layer 2: 35 μm

Prepreg 1080 RC63%: 0.0644 mm (2.5 mil)

Copper Layer 3: 35 μm

S1000-2M: 0.203 mm (3 mil)

Copper Layer 4: 35 μm

Prepreg 1080 RC63%: 0.0644 mm (2.5 mil)

Copper Layer 5: 35 μm

RO4003C: 0.305 mm (12 mil)

Copper Layer 6: 35 μm

PCB Statistics

Components: 22

Total Pads: 39

Through Hole Pads: 21

Top SMT Pads: 18

Bottom SMT Pads: 0

Vias: 21

Nets: 5

Standards and Availability

Artwork Type: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide

Typical Applications

Commercial airline broadband antennas

Microstrip and stripline circuits

Millimeter-wave applications

Radar systems

Guidance systems

Point-to-point digital radio antennas

In summary, RO4003C and Tg170 FR-4 are high-performance materials ideal for a range of applications in the PCB industry, providing excellent reliability and efficiency for high-frequency designs.